Every water storage system relies on one crucial element — its liner. For facilities across Melbourne, PVC tank liners protect water quality, prevent leaks, and extend the lifespan of storage assets.

However, even the most durable liners degrade over time due to UV exposure, pressure fluctuations, or chemical reactions.

That’s why regular inspection by Tank Inspections Melbourne by Raven Tanks Australia is essential to maintain both performance and compliance.

What is a PVC Tank Liner Inspection?

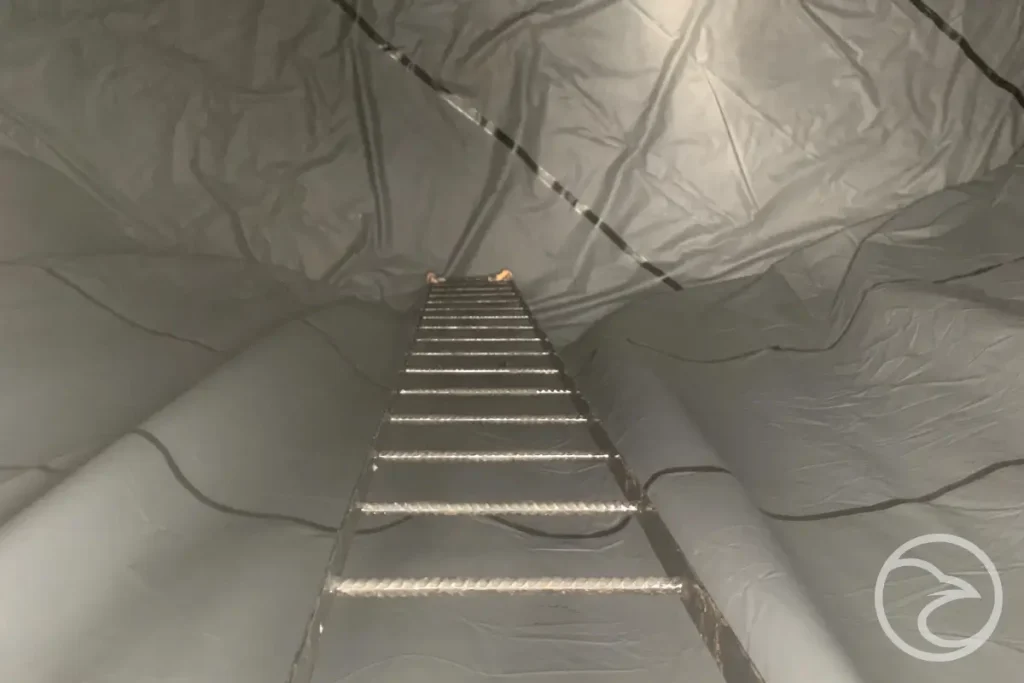

A PVC tank liner inspection is a professional assessment that evaluates the physical integrity, seal condition, and chemical resistance of the liner. During the process, experienced inspectors check for:

- small punctures or abrasions,

- joint separations or weld fatigue,

- liner displacement from the tank base,

- microbial growth or contamination,

- and signs of chemical erosion from stored liquids.

At Tank Inspections Melbourne by Raven Tanks Australia, certified technicians use advanced leak detection tools and non-invasive testing to ensure your system stays watertight and safe.

Key Benefits of Regular PVC Liner Inspections

Ignoring liner maintenance can lead to costly issues — from contaminated water to complete tank failure. Proactive inspections offer major advantages, including:

- Leak Prevention: Early detection of micro-leaks prevents environmental damage and reduces water loss.

- Extended Service Life: Regular inspection allows minor repairs before they escalate, extending liner lifespan by several years.

- Compliance with Australian Standards: Routine inspections help facilities meet local safety and water storage standards, avoiding fines or shutdowns.

- Improved Water Quality: A clean, undamaged liner protects potable and industrial water from debris, sediment, and bacterial contamination.

Inspection Process by Tank Inspections Melbourne

Each project is tailored to your system type and industry — whether it’s a commercial fire tank, industrial process tank, or stormwater detention system.

The inspection typically includes:

- Visual & Surface Check – Assessing visible wear, surface separation, and anchor integrity.

- Leak Detection Test – Using hydrostatic pressure or ultrasonic sensors to find hidden weaknesses.

- Liner Flexibility Analysis – Evaluating elasticity and strength, especially for older PVC materials.

- Documentation & Reporting – Detailed reports with photos, recommendations, and compliance notes.

- Maintenance or Repair Scheduling – If defects are found, the team arranges prompt patching or replacement.

This method ensures that every PVC liner continues to perform under the toughest Australian conditions.

When to Schedule an Inspection

To maintain compliance and prevent structural damage, it’s recommended to schedule PVC tank liner inspections at least once every 12 months.

Additional checks are necessary:

- after any major storm or heatwave,

- following a chemical spill or contamination event,

- or before refilling long-idle tanks.

For high-demand industrial sites, a semi-annual inspection ensures continuous reliability.

Partnering with Experts You Can Trust

Choosing Tank Inspections Melbourne by Raven Tanks Australia means working with a team that understands every aspect of PVC liner systems — from design and fabrication to installation and repair.

Their inspection services combine:

- cutting-edge technology,

- certified inspection protocols,

- and decades of experience in the Australian tank industry.

Whether your system stores potable water, wastewater, or fire protection reserves, the right inspection plan keeps it compliant, leak-free, and efficient year-round.

Conclusion: Protect Your Storage Investment

PVC tank liners are built to last — but only with the right care. Regular inspections safeguard your infrastructure, prevent costly repairs, and ensure long-term water quality.

Contact Tank Inspections Melbourne by Raven Tanks Australia for a full assessment and keep your system performing at its best.